For some things, being off just a little isn’t a big deal. However, that’s not the case when it comes to fabricated products. Along with precision-made parts or components, customers require a fast turnaround on the product ordered. Without both, they could face major challenges with internal operations or meeting the demand of end-users. This is why choosing the right company for sheet metal fabrication is important.

Fortunately, the best sheet metal companies have both experience and knowledge that allows them to identify and rectify issues quickly. Even then, problems can arise. Considering the growing need for sheet metal fabrication services in Toronto and with this being a highly competitive industry, it’s never OK to deliver a subpar product or get parts and components to the customer late.

The following are some of the reasons that these events occur:

Qualified Labor – Sheet metal fabrication is both an art and science. Although many of the machines used today have automated features, there’s still the need for an operator to oversee the process from start to finish. The main issue is that some companies don’t provide their personnel with adequate training. As a result, any number of problems can arise without detection.

Poor Quality Raw Material – If you want the best sheet metal fabrication service in Toronto, make sure you select a company that works with superior quality raw materials. Yes, skill and equipment play a pivotal role in the quality of fabricated parts and components. However, it starts with the material used. In addition to quality, choose a fabricator that offers a broad range of materials. That way, you’ll have one trusted source that can accommodate all your needs.

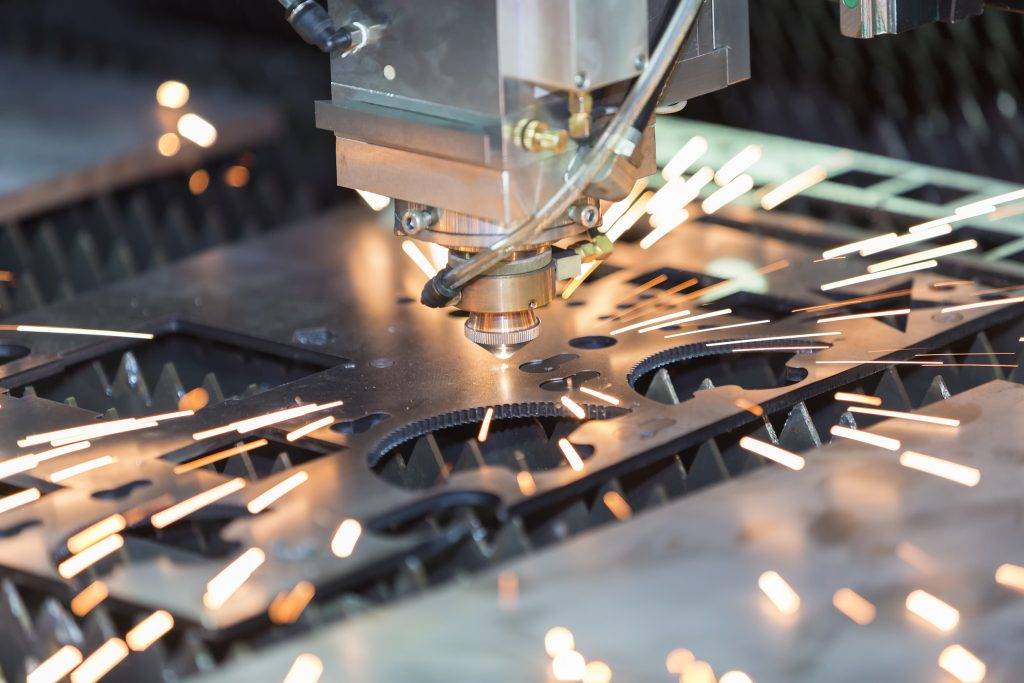

Technologies – Another cause of poor-quality products and late deliveries has to do with a lack of modern-day technologies. Especially in this market, things change quickly and frequently. For sheet metal companies to keep up with customers’ demands while meeting their specifications, they need to adopt and implement state-of-the-art technologies as part of the fabrication process.

Full-scope Services – Not only does sheet metal fabrication require a skilled operator but also a full team of experts. By working together, this ensures the satisfaction of every customer. In particular, the best sheet metal companies have a broad range of capabilities, including engineering design, shearing and cutting, CNC turret punching, and hardware insertion, and the list goes on. The more professionals there are working toward a common goal, the better the quality of the fabricated parts and components, and the faster the turnaround.

Continue Reading for more details.

Contact Details :

Weldflow Metal Products

3425 Semenyk Ct Mississauga, L5C 4P9 Ontario

Business Email : info@weldflowmetal.com

Business Phone Number : 905-277-0006